Model | Description | Tube Type and OD Range (Dependent on Tube Gauge) | Applicable Deposits |

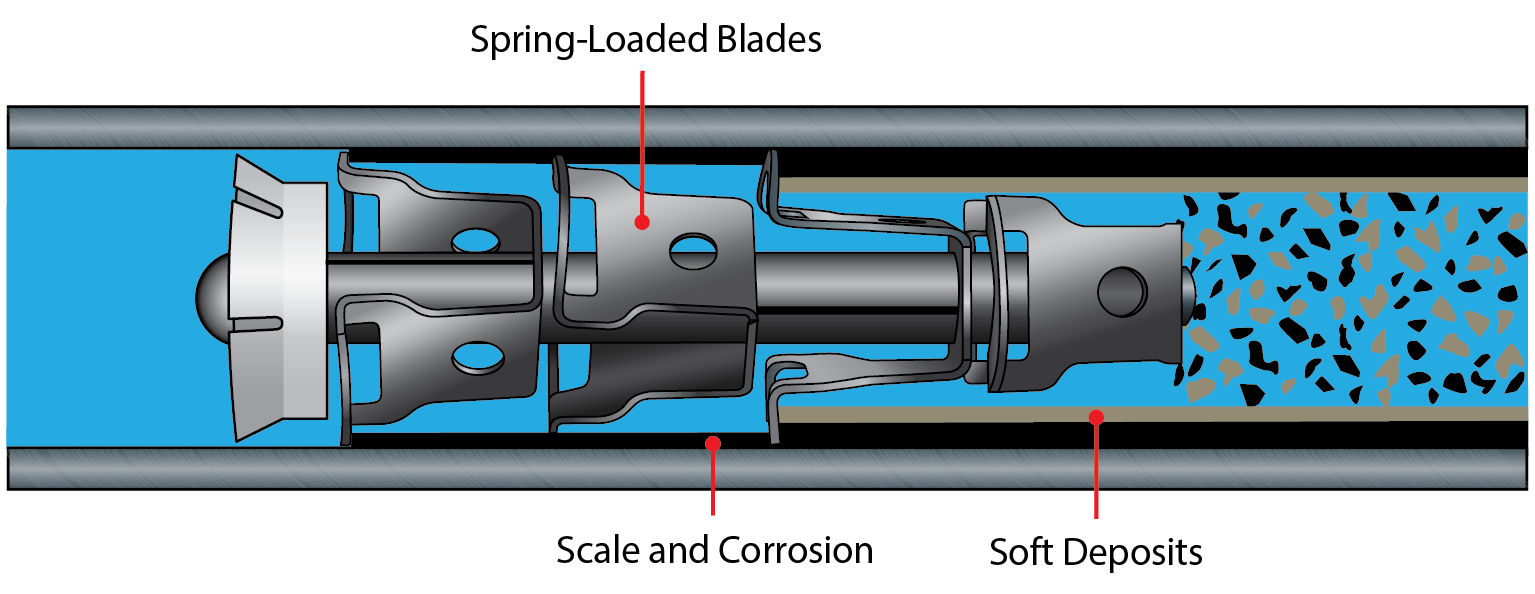

C4S  | All Purpose Tube Cleaner Four-stage design with spring-loaded blades and travels through the tube at 10 to 20 feet per second (at 200-300 PSI) | Straight Tubes Only: 1/2” to 1-1/2” | All types of deposits, including - Microbiological fouling: biofouling, slime and organisms

- Particulate fouling: deposition, silt and mud

- Chemical reaction fouling: corrosion deposit, Cu2O, and chemical product

- Macrobiological fouling; shells, clams, mussels, debis and obstructions

- Corrosion and pitting by-products

|

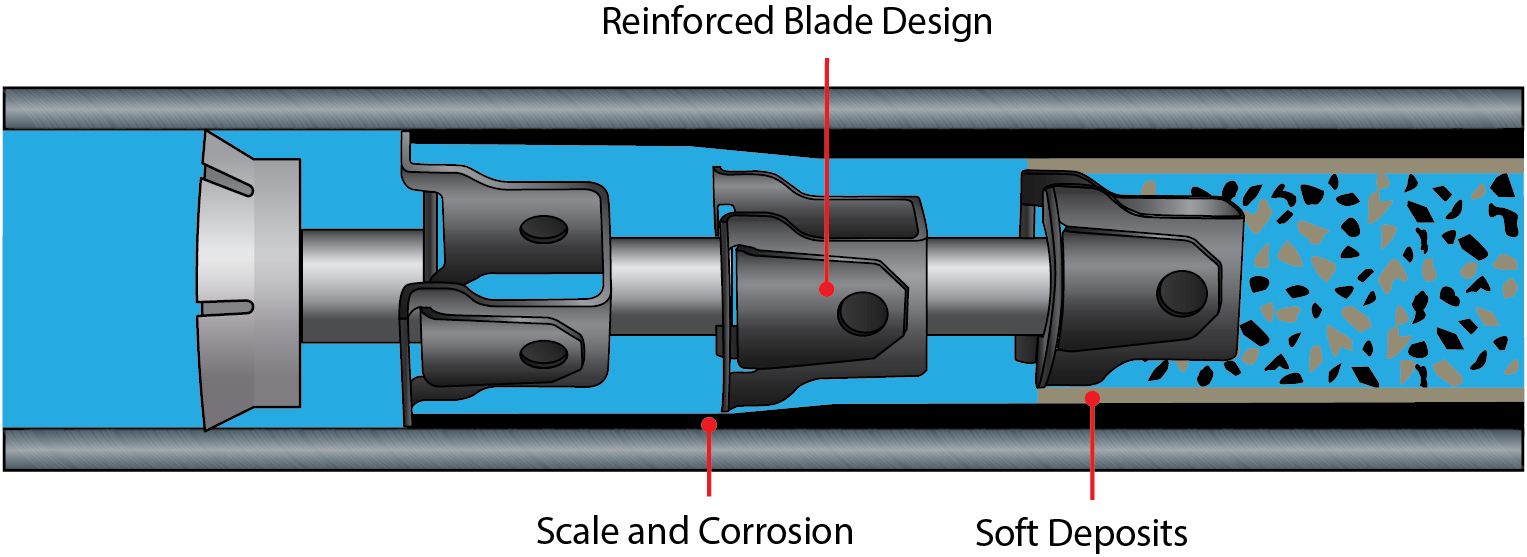

C3S  | Heavy Duty Tube Cleaner Three-stage design with reinforced blades and travels through the tube at 10 to 20 feet per second (at 200-300 PSI) | Straight Tubes Only: 7/8” and 1” | Hard deposits, including - Chemical reaction fouling: corrosion deposit, Cu2O, and chemical product

- Crystallization fouling: scale, iron, manganese and calcium carbonate

- Corrosion and pitting by-products

|

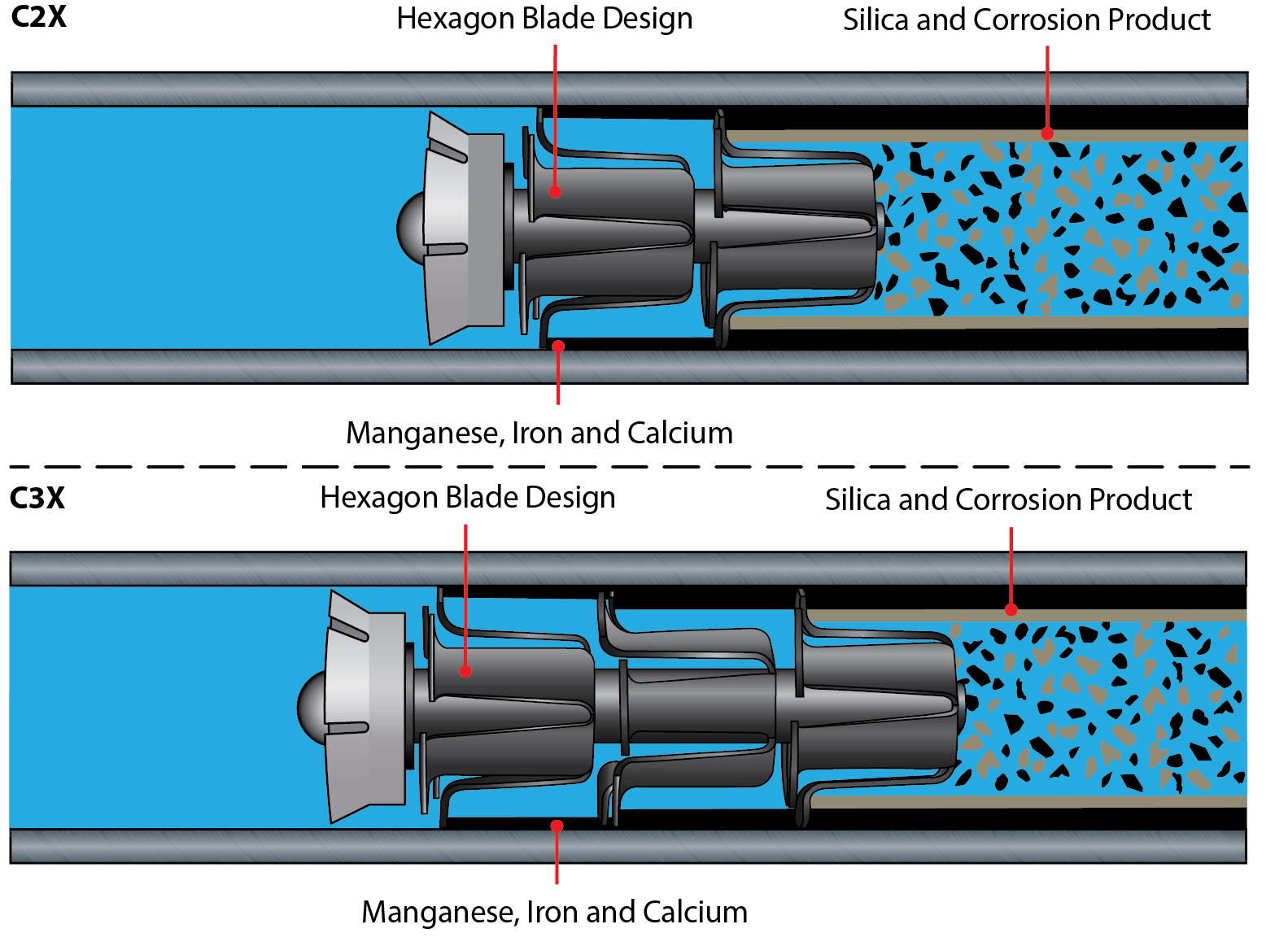

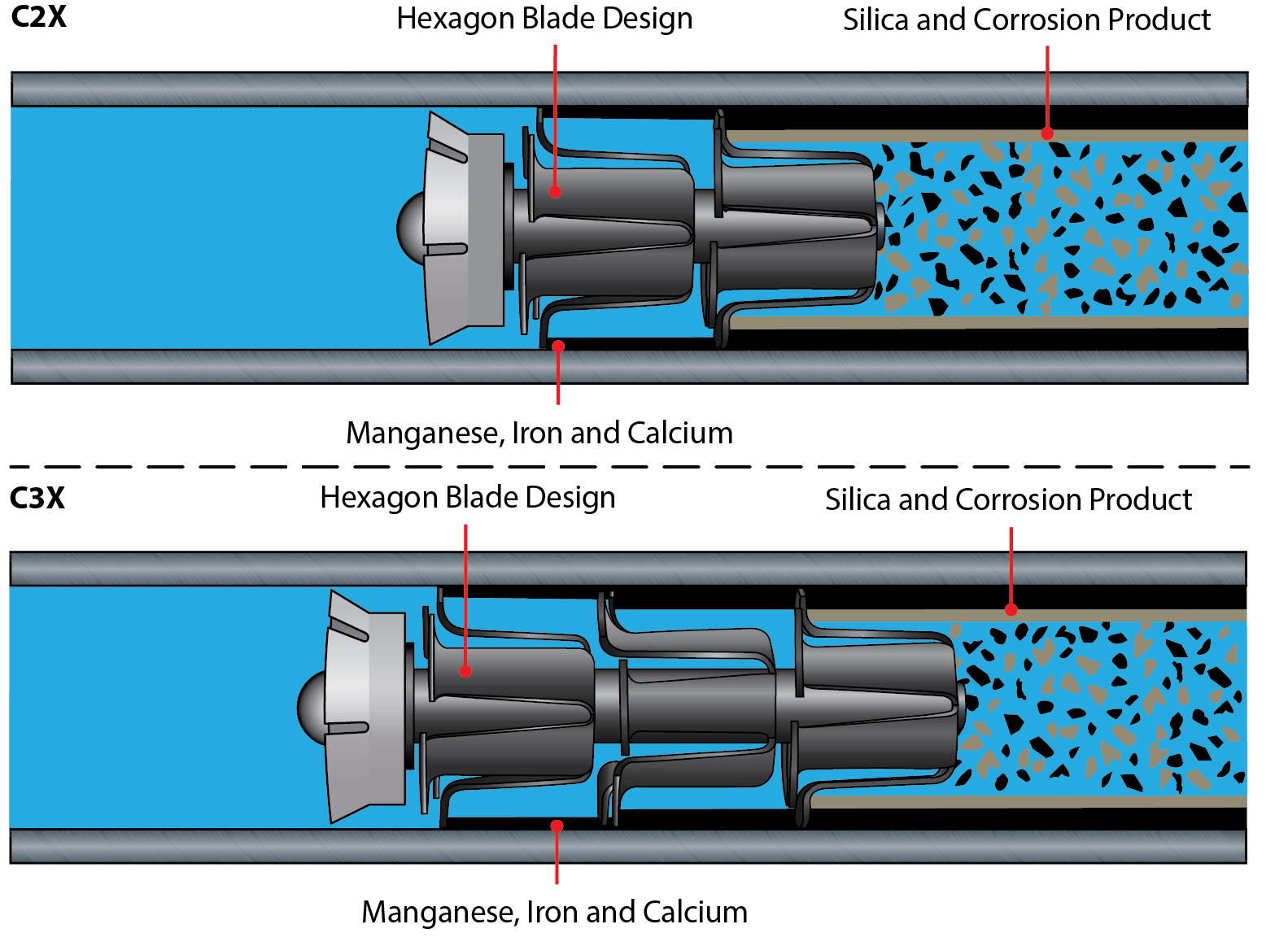

C2X / C3X  | Hex Tube Cleaner Two-stage or three-stage design with hexagon shaped blades and travels through the tube at 10 to 20 feet per second (at 200-300 PSI) | Straight Tubes Only: 3/4” to 1-1/4” | Thin tenacious deposits, including - Chemical reaction fouling: corrosion deposit, Cu2O, and chemical product

- Crystallization fouling: scale, iron, manganese, silica and calcium carbonate

- Corrosion product

- Other types of debris and obstructions

|

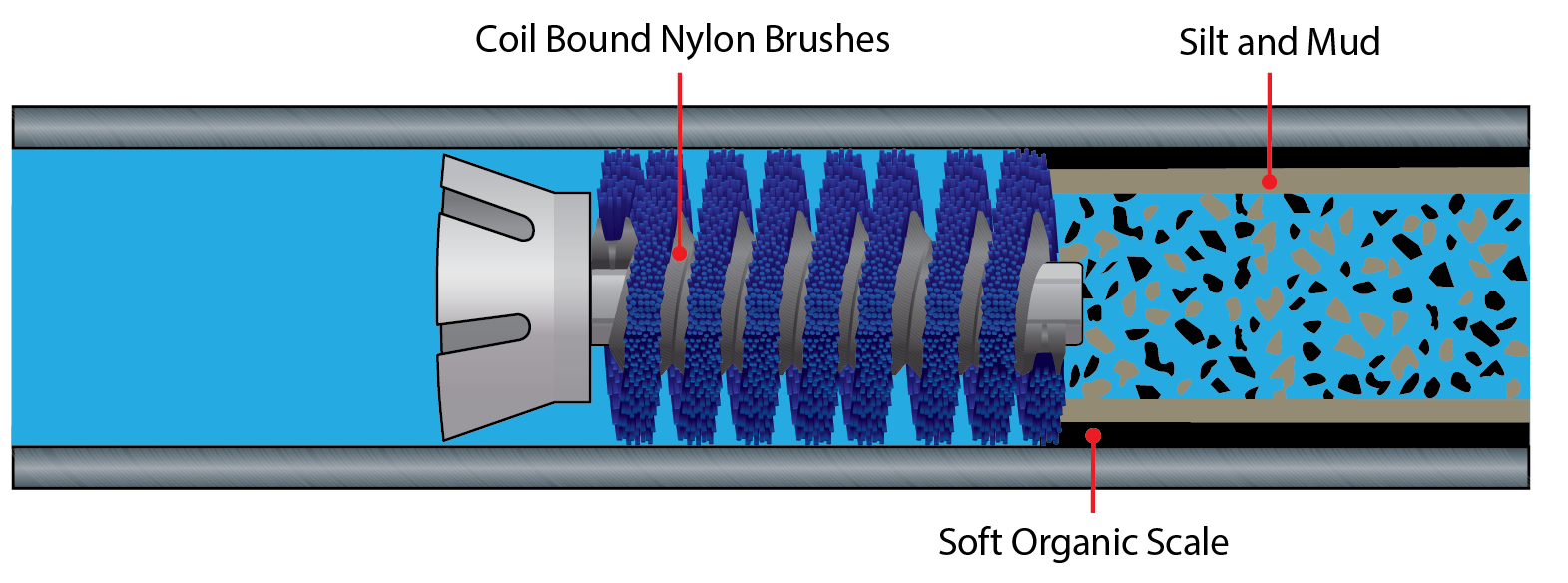

H-Brush  | H-Brush Tube Cleaner Coil-bound nylon bristles and travels through the tube at 10 to 20 feet per second (at 200-300 PSI) | Straight Tubes Only: 5/8” to 1-1/2” | Soft deposits, including - Microbiological fouling: biofouling, slime and organisms

- Some corrosion by-products

- Most types of obstructions

|

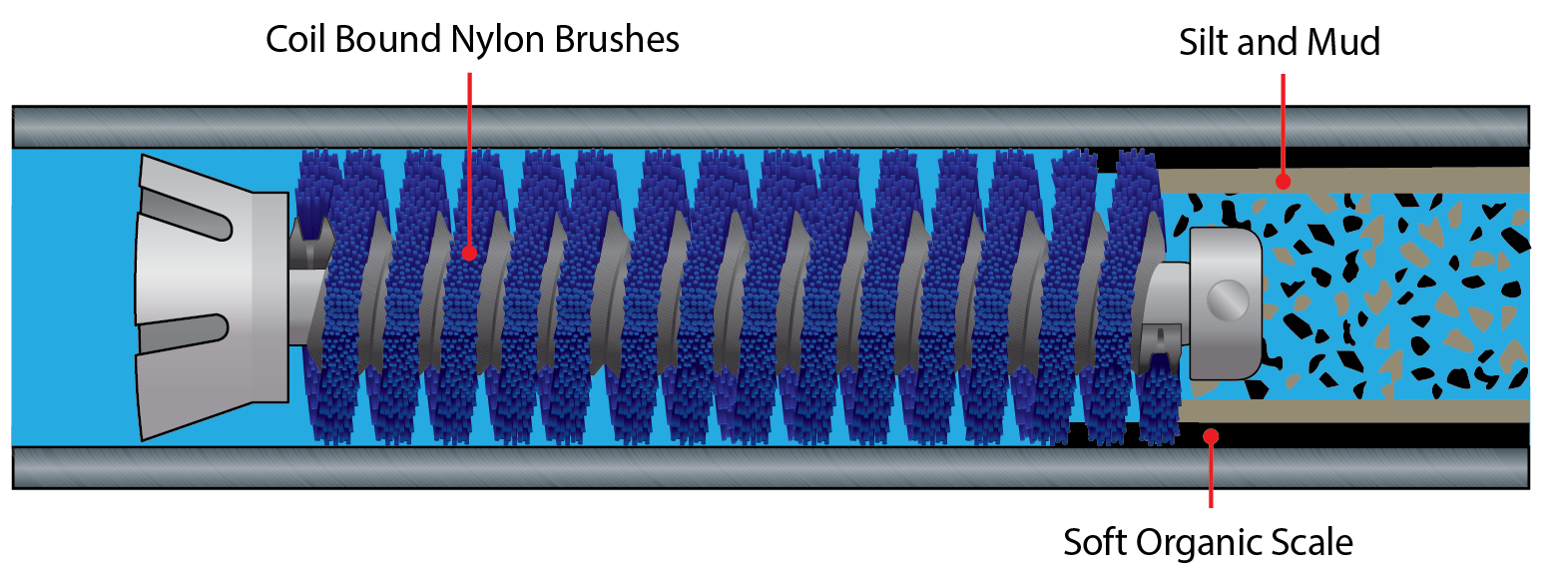

XL-Brush  | XL-Brush Tube Cleaner Extra-long coil-bound nylon bristles and travels through the tube at 10 to 20 feet per second (at 200-300 PSI) | Straight Tubes Only: 5/8” to 1-1/2” | Soft deposits, including - Microbiological fouling: biofouling, slime and organisms

- Some corrosion by-products

- Most types of obstructions

|

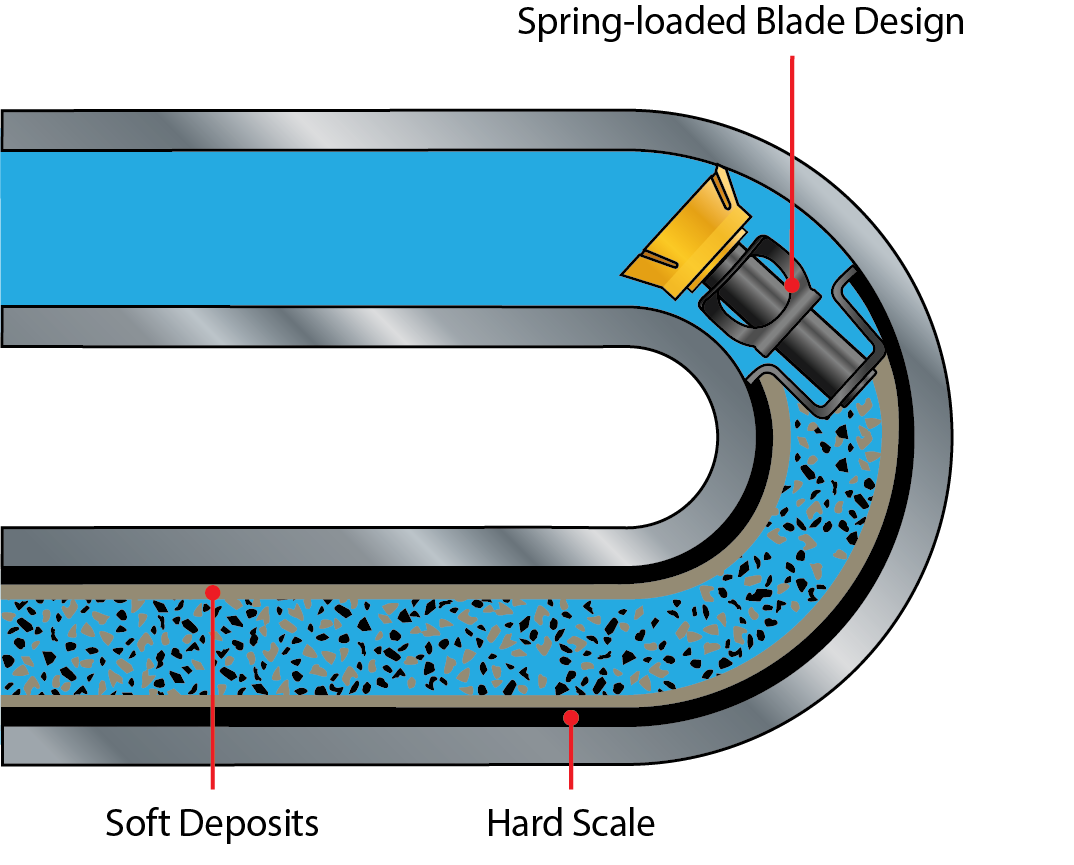

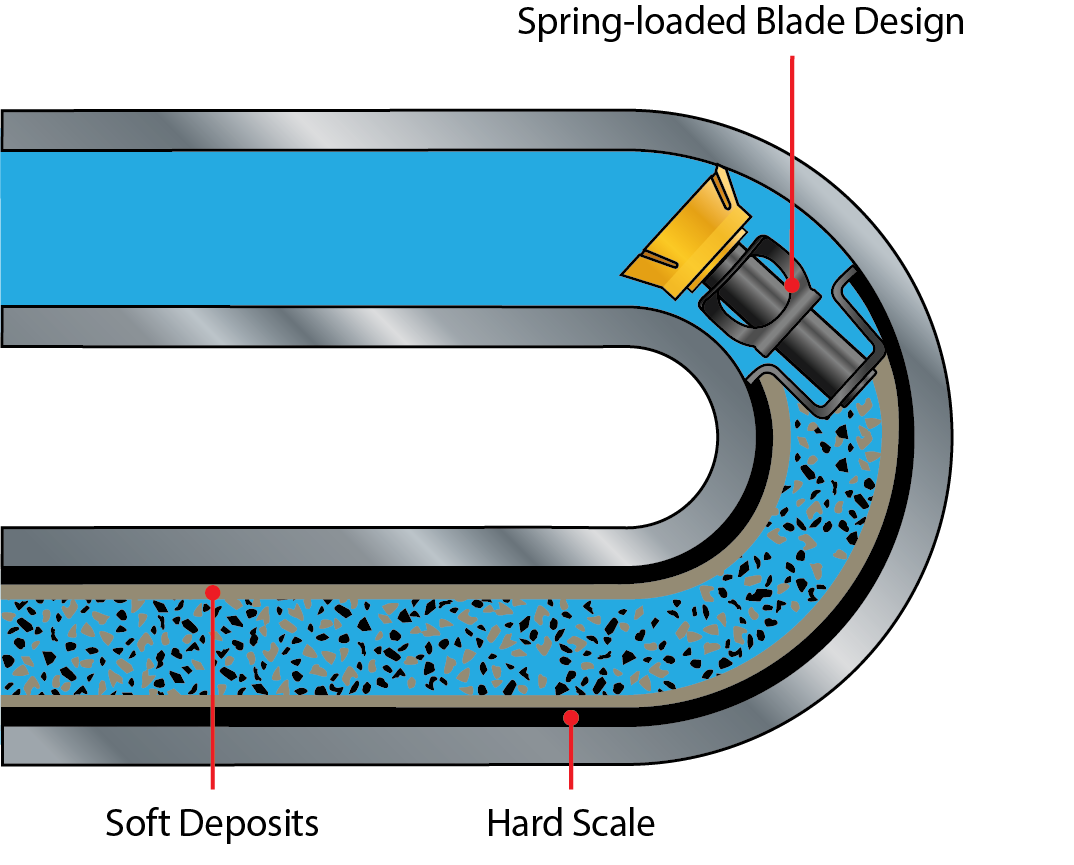

C2S  | Metal U-Tube Cleaner Two-stage design with spring-loaded blades and travels through the tube at 10 to 20 feet per second (at 200-300 PSI) | U-Bend Tubes Only 5/8" to 1-1/4" | All types of deposits, including - Microbiological fouling: biofouling, slime and organisms

- Particulate fouling: deposition, silt and mud

- Chemical reaction fouling: corrosion deposit, Cu2O, and chemical product

- Crystallization fouling: scale, iron, manganese, silica and calcium carbonate

- Macrobiological fouling; shells, clams, mussels, debis and obstructions

- Corrosion and pitting by-products

|

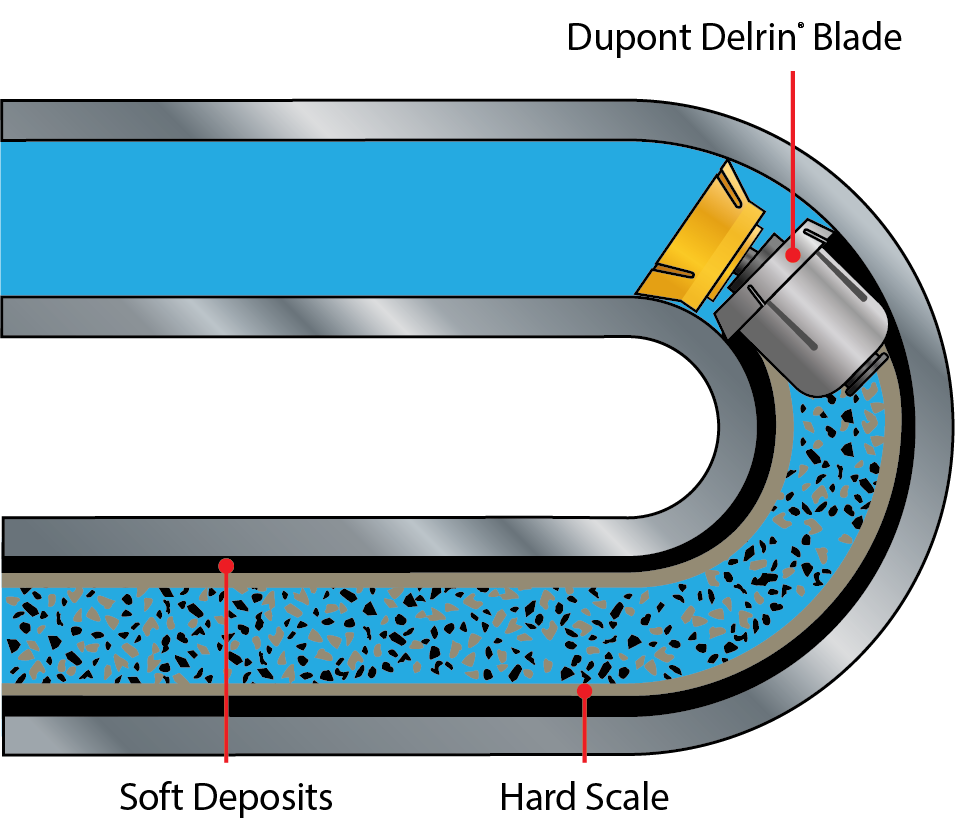

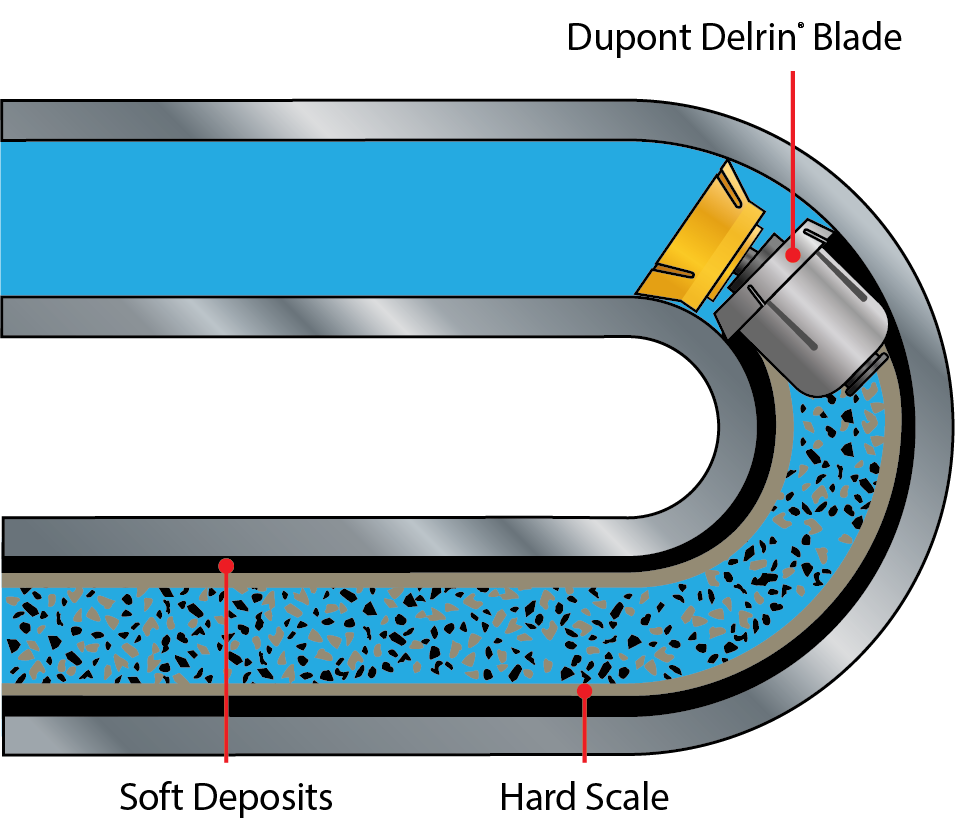

Plastic U-Tube  | Plastic U-Tube Cleaner Single-stage design with a DuPont Delrin® cleaning surface capable of navigating very tight radiuses and travels through the tube at 10 to 20 feet per second (at 200-300 PSI) | U-Bend Tubes Only 1/2” to 1-1/4” | All types of deposits, including - Microbiological fouling: biofouling, slime and organisms

- Particulate fouling: deposition, silt and mud

- Chemical reaction fouling: corrosion deposit, Cu2O, and chemical product

- Crystallization fouling: scale, iron, manganese, silica and calcium carbonate

- Macrobiological fouling; shells, clams, mussels, debis and obstructions

- Corrosion and pitting by-products

|

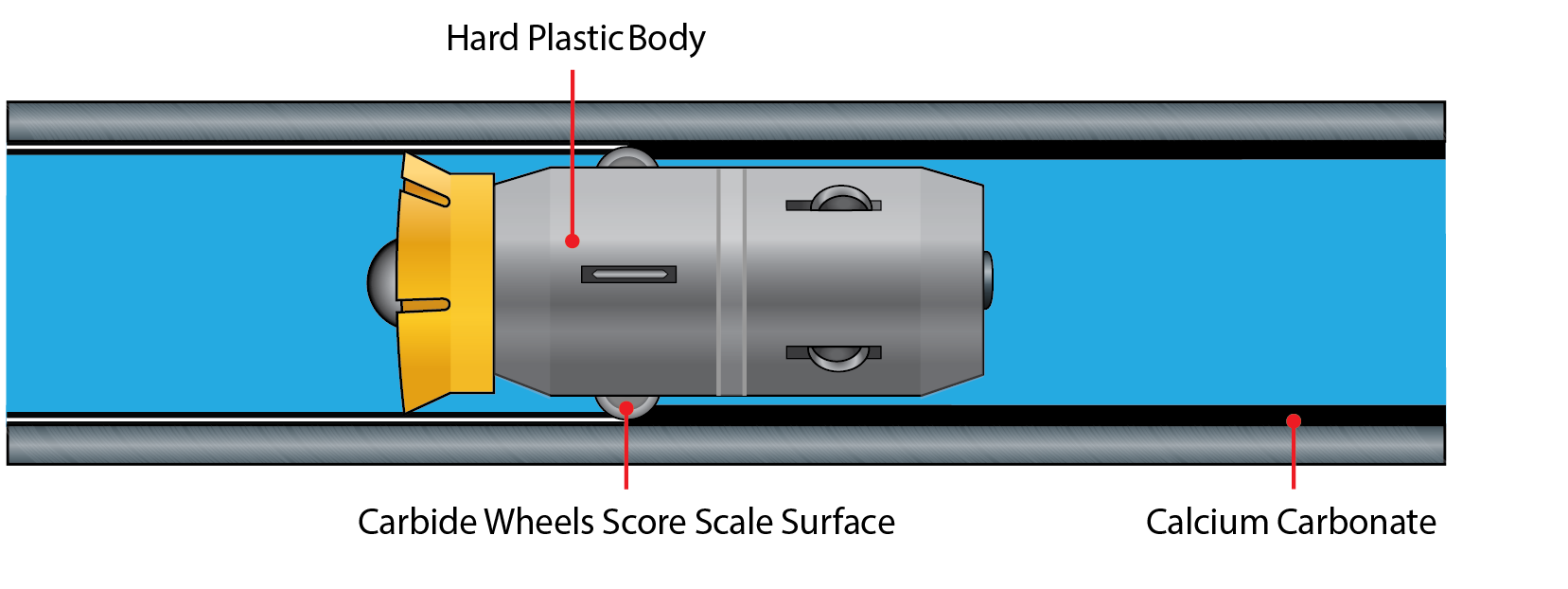

Cal-Buster®  | Cal-Buster Tube Cleaner Two-staged DuPont Delrin® body each containing four carbide cutting wheels and travels through the tube at 10 to 20 feet per second (at 200-300 PSI) while the carbide wheels “score” the surface of the calcium, making removal possible with a Conco C4S or C3S type cleaner | Straight Tubes Only: 3/4” to 1-1/4”

*on-site evaluation and inspection is required to determine critical sizing information | Eggshell-like crystalline form of calcium-based scale deposits |

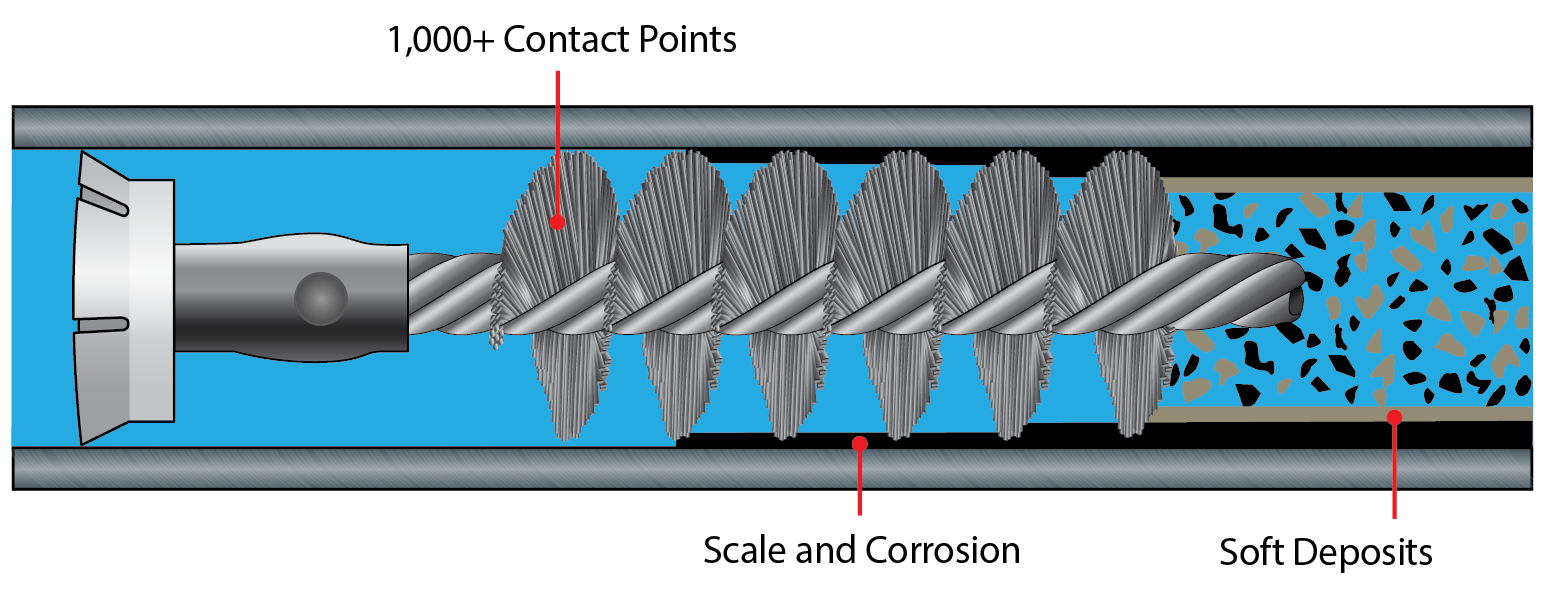

QTB  | Stainless Steel Twist Brush Tube Cleaner Over 1000 stainless bristles and travels through the tube at 10 to 20 feet per second (at 200-300 PSI) | Straight Tubes Only: 5/8” to 1-1/4” | Light deposits, including - Chemical reaction fouling: corrosion deposit, Cu2O, and chemical product

- Crystallization fouling: scale, iron, manganese, silica and calcium carbonate

- Macrobiological fouling; shells, clams, mussels, debis and obstructions

|

Type P  | Plastic Tube Cleaner Multi-stage design with plastic blades and travels through the tube at 10 to 20 feet per second (at 200-300 PSI) | Straight Tubes Only: 5/8” to 1-1/4” | Softest types of deposits, including - Microbiological fouling: biofouling, slime and organisms

|