Nondestructive Testing Services

For Eddy Current, Remote Field and Near Field Testing of your heat exchanger tubes...count on Conco for fast, reliable, and accurate results.

Conco Nondestructive Testing (NDT) services are performed on all types of tubing in heat exchangers and condensers included in the steam cycle, cooling water, service water systems and process systems. Nondestructive Testing helps to prevent forced shut downs by detecting various defects such as pitting, cracking, corrosion, erosion, grooving, steam impingement and tube-support fretting that cause tube failures. Our customers realize significant economic savings from routine testing through improved reliability and plant availability. Conco NDT personnel are certified in accordance with the American Society of Nondestructive Testing (ASNT) SNT-TC-1A guidelines. Quickly capture accurate data on equipment integrity and prevent forced shut downs.

Cross Trained Crews

Provide quality clean and test services eliminating complications between multiple vendors, resulting in a reduction of downtime and headcount on-site.

Testing Capabilities

Conco offers a variety of testing capabilities to match your inspections needs. Most employees are cross trained in all methods to increase productivity and effectiveness.

| TEST METHOD | ABBREVIATION | TEST TYPE | DESCRIPTION |

| Eddy Current Testing | ECT | Electromagnetic | Determine % wall loss on non-ferromagnetic heat exchanger and condenser tubing |

| Eddy Current Array Testing | ECA | Electromagnetic | Determine % wall loss on non-ferromagnetic heat exchanger and condenser tubing with heightened sensitivity to smaller volume damage mechanisms with additional coils on probe |

| Surface Eddy Current Testing | SET | Electromagnetic | Determine % wall loss or cracking on ferromagnetic or non-ferromagnetic surfaces and sub-surfaces including heat exchangers, condensers, columns, vessels, drums and tanks |

| Surface Array Eddy Current Testing | SETA | Electromagnetic | Determine % wall loss or cracking on ferromagnetic or non-ferromagnetic surfaces and sub-surfaces including heat exchangers, condensers, columns, vessels, drums, and tanks with heightened sensitivity to smaller volume damage mechanisms with additional coils on probe |

| Saturation Eddy Current | ECTSAT | Electromagnetic | Determine % wall loss on specialty materials in heat exchanger and condenser tubing, such as Duplex SS, Monel, Monel 400, Nickel 200, Seacure |

| Remote Field Testing | RFT | Electromagnetic | Determine % wall loss on ferromagnetic heat exchanger and condenser tubing |

| Array Remote Field Testing | RFTA | Electromagnetic | Determine % wall loss on ferromagnetic heat exchanger and condenser tubing with heightened sensitivity to smaller volume damage mechanisms closer to tube sheet and supports with additional coils on probe |

| Near Field Testing | NFT | Electromagnetic | Determine % wall loss on ID of ferromagnetic fin fan air cooler tubing |

| Near Field Array Testing | NFA | Electromagnetic | Determine % wall loss on ID of ferromagnetic fin fan air cooler tubing with heightened sensitivity to smaller volume damage mechanisms closer to tube sheet and header box with additional coils on probe |

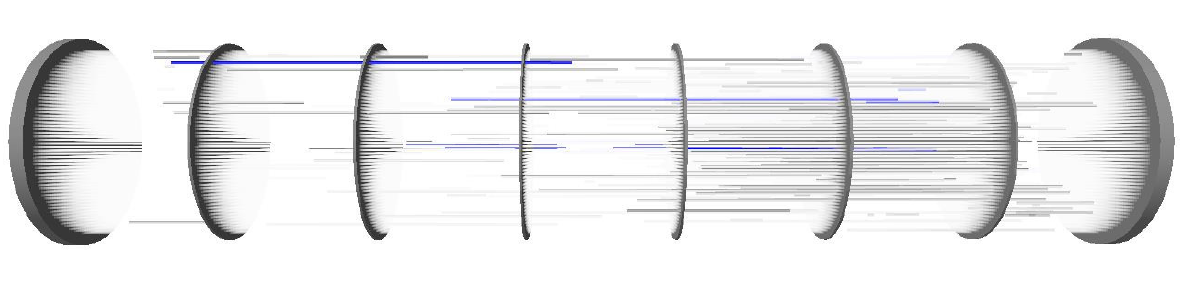

| Internal Rotating Inspection System | IRIS | Ultrasonic | Determine exact wall thickness on any material (ferromagnetic, non-ferromagnetic) heat exchanger, condenser, and fin fan air cooler tubing or piping |

| Ultrasonic Thickness Testing | UTT | Ultrasonic | Determine wall thickness of spot on nozzles, shells, or piping |

| Mechanical Integrity | API 510 / 570 / 653 | Visual | Visual inspection for corrosion on tubing, piping, and surfaces |

| Video Inspection | RVI | Visual | Visual inspection for corrosion on tubing, piping, and surfaces |

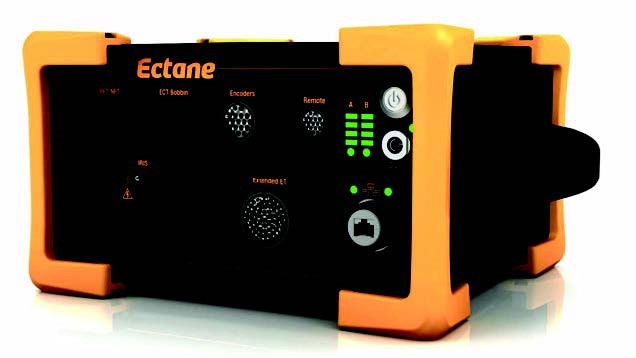

Equipment

Conco Services utilizes the best testing equipment on the market which offers a diversified portfolio of NDT instruments, sensors, software, and robotic solutions for the inspection of critical components and assets in key industries such as aerospace, oil & gas, and power generation. Conco Services has a large inventory of probes and standards of various sizes and materials giving us the ability to inspect a wide range of tubing specifications.

Data Analysis & Reporting

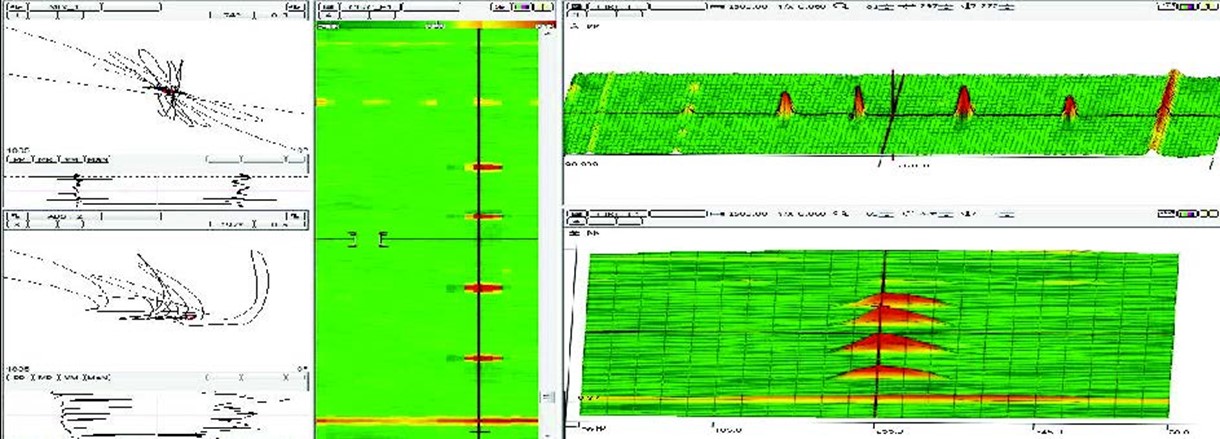

Depending on your requirements, Conco NDT analysts can provide on-site or remote data analysis, utilizing the most advanced software for NDT testing. Our analysts will identify defects in your heat exchanger tubing and provide a comprehensive final report of their findings. We can even assist you in the establishment of a nondestructive testing program. This allows Conco to trend the growth of previously identified damage within the heat exchanger. It also allows us to monitor for any new damage mechanisms that may occur during the operation cycle. Conco offers a quick turnaround on its final reports. A final report will be issued within hours if not before the crew leaves site.

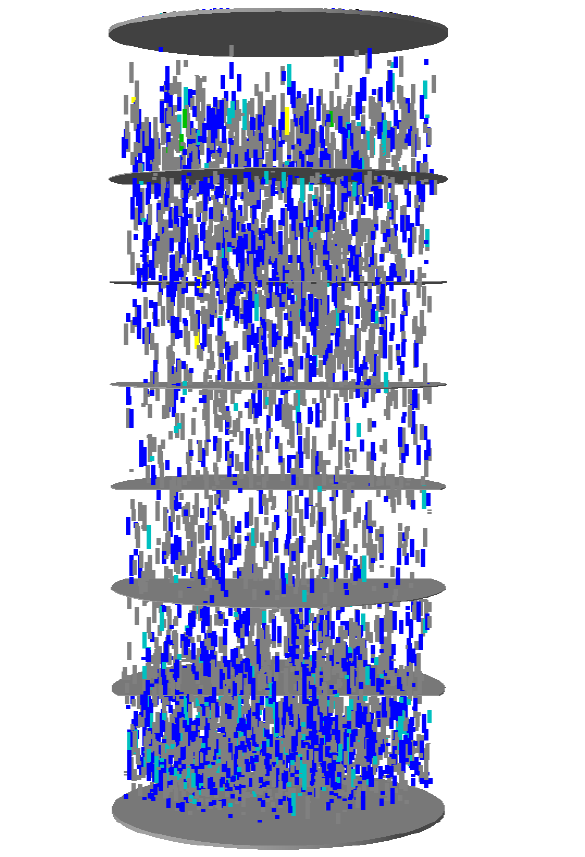

Analysis Software and Array C Scan

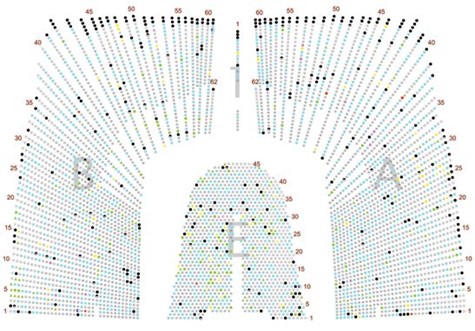

Tubesheet Mapping

This service provides an at-a-glance summary of heat exchanger condition. Upon completion of a comprehensive nondestructive testing evaluation, Conco can create a multicolor tubesheet map for graphic illustration of tube wall condition. The overall condition of the heat exchanger and any developing trends are obvious as each tube's condition is represented by a different color or symbol.