Conco Alkaserts® are widely used in electric power stations, industrial power plants and onboard ships – wherever inlet end tube erosion and impingement present a problem. They are designed to assure lasting protection to the inlet ends of new tubes and greatly prolong the life of worn tubes damaged by erosion or impingement. Alkaserts® are inert and highly resistant to erosion and abrasion. They are dimensionally stable well above normal operating temperatures of steam condensers. Alkaserts® are flexible enough to accommodate normal variations in tube bores, yet rigid enough for easy insertion. They are designed to make a snug fit in the tube so that there is no danger of water seeping between the insert and tube.

Two Head Designs Available

The "bonnet" head is designed

to cover the ferrule in

ferrule-type installations

The "flush" type head is designed

for flush rolled-in tubes and close

clearance tube sheet designs

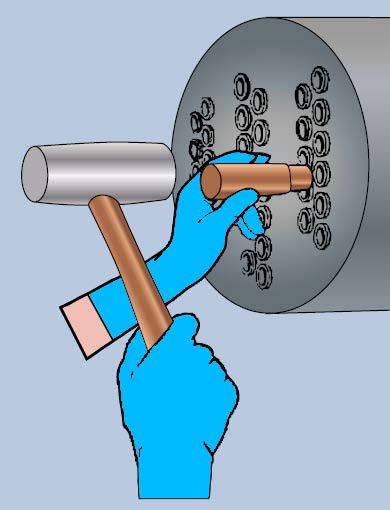

Quick and Easy Installation

After applying the appropriate adhesive, push Alkasert® into tube and tap with wooden mallet and installation tool until the insert is fully seated into tube.

Features

- Easy, quick installation

- Conforms to irregular tube surface conditions – streamlining flow over these areas

- Dimensionally stable to 170°F, well above normal operating temperatures of steam condensers

- Unaffected by normal cleaning chemicals

- Filtering action – holds foreign objects for easy removal

- Can be left in place for cleaning with most Conco tube cleaners (consult with your sales representative)

- Available for a wide range of tube sizes and gauges