Steam Blow

Design, engineer, and execute steam blowing to ensure your system meets OEM cleanliness specifications. Commission your steam system with confidence and eliminate delays with our experienced engineering and field service teams whose track record has been proven worldwide.

Features

- Engineer thoroughly plans the procedure including:

- Number of exit points

- Type of blow

- Temporary piping requirements

- Cleaning force ratio

- Steam flow conditions

- Isometric drawings of temporary piping, bill of materials and execution procedures produced by engineer

- Coverage of full project scope including engineering, fabrication, and on-site supervision to oversee setup and execution

- Steam is blown at velocity and pressure predetermined by the engineer, then vented via temporary piping before reaching the critical component

- Remotely actuated target inserters allow for safe introduction and removal of the target into the steam flow

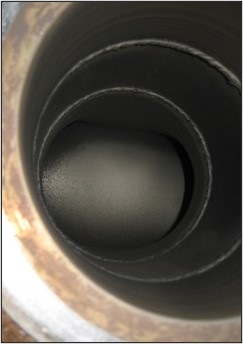

- Visual inspection of target or steam plume to verify cleanliness standards are met

- Silencers combined with water quenching available to reduce noise at exit points

- Post job report is provided

BEFORE | AFTER |

|  |