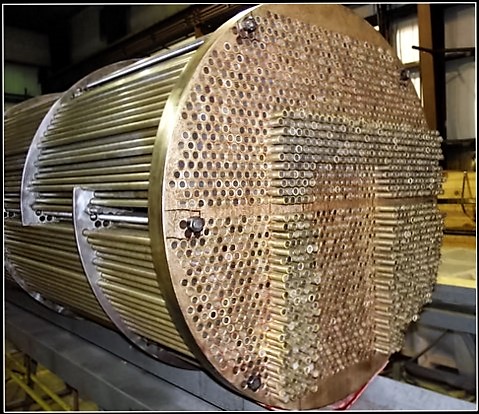

Retubing

Conco’s retubing crews will execute a full retube, partial retube, or single tube replacement quickly to get your unit back online faster than the OEM without the cost of complete replacement. If needed, our team can reverse engineer, re-manufacture, or build you a new heat exchanger bundle in a fraction of the delivery time required to order new factory units.

Features

- Established relationships with many tube suppliers across the US to supply a wide variety of tubing materials, sizes, and wall thickness for both finned and smooth tubes

- On-site or off-site services available

- Crews have over 30 years experience with appropriate tooling

- Units cleaned and hydro tested after retube